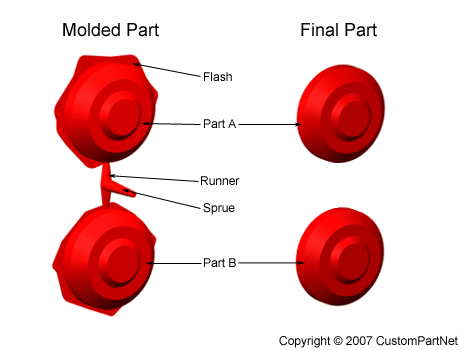

Flash

Flash is a small burr formed around the parting line of the moulding and is normally formed when the mould opens slightly during the filling or holding phase.

Flash can also from on a new mould during the commissioning stage if the two halves are not fully bedded out.

Flash often forms when moulding very low viscosity materials, as the melt can flow into the thinnest of gaps.

Solution:

1. Ensure the mould is bedded out properly.

2. Reduce the injection speed.

3. Reduce the maximum cavity pressure during injection or hold.

4. Reduce the melt temperature.

5. Check rigidity of the mould and machine platen.

6. Check material viscosity is within specification.

7. Consider running the mould on a machine with higher clamp force.